Fewer manufacturers experienced a failure in testing for the 2022 Scorecard than in 2021. However, the BOM-level failure rate remained the same: 26% of BOMs experienced at least one failure.

Failures in Testing

“Enerparc takes quality seriously; we leverage PVEL’s detailed test reports to make procurement decisions. While we believe that Top Performer recognition is an encouraging indictor of product reliability, we review the detailed test reports and will not source modules that exhibit any type of failure in PVEL’s Product Qualification Program for our projects.”

Erik Lohse, Team Leader Quality Management, Enerparc

Key Takeaways

Click through the key takeaways below.

Some manufacturers experienced no failures and others had multiple

Although a similar share of bills of materials (BOMs) experienced at least one failure in 2022 and 2021, just one manufacturer accounted for 40% of all failures in the 2022 Scorecard.

Damp heat failures increased, but not for most manufacturers

More BOMs experienced failure in damp heat testing than in any other test, but less than 15% of manufacturers experienced a DH-related failure.

Junction box issues are a primary driver of failure

In the last four successive Scorecards, we have observed persistent safety concerns with junction boxes. They remain a common source of failure, with 30% of participating manufacturers having one or more junction box related failures.

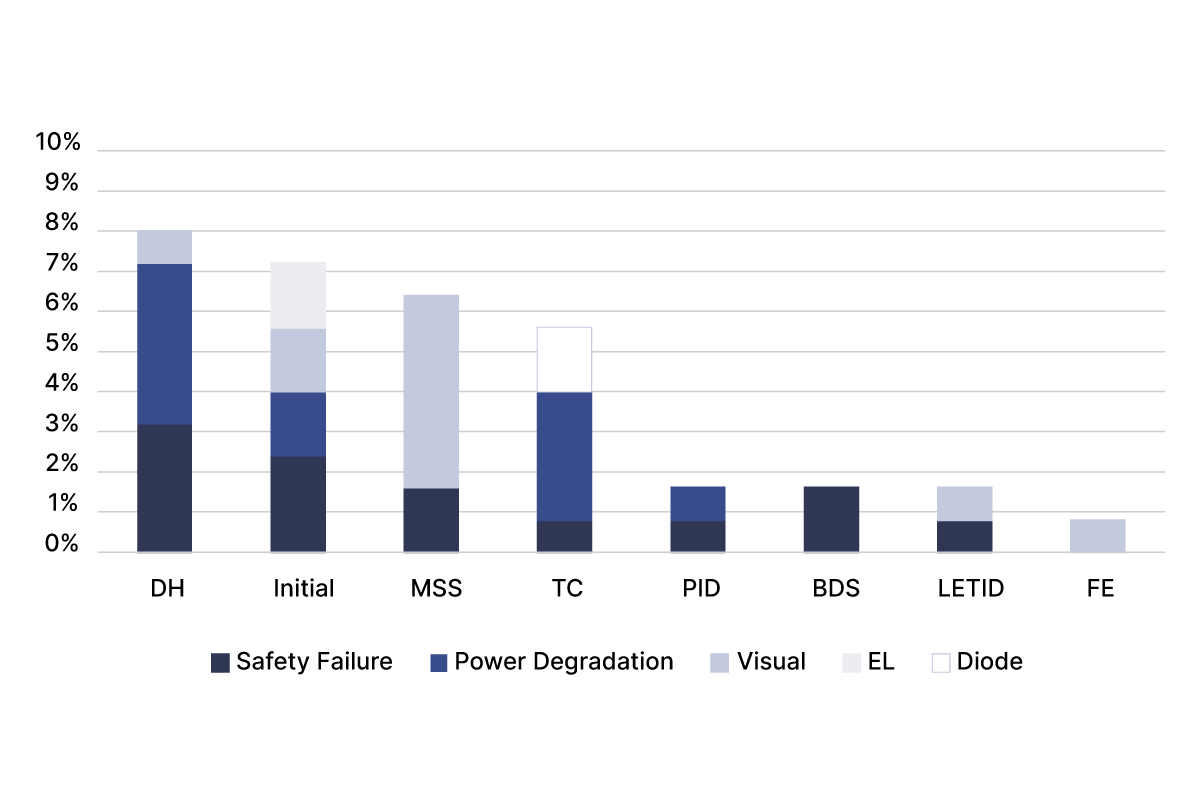

PQP Failure Statistics

This graph shows failures observed in each test sequence of the PQP by type of failure.

The most common type of failure is safety, followed closely by power degradation and visual inspection defects.

Initial failures are those that were detected during intake characterizations prior to testing.

Go beyond model types. Procure PV modules with top-performing bills of materials.

Join PVEL’s downstream partner network.

Sign Up