PVEL’s Hail Stress Sequence (HSS) replicates the impact energy of natural hail and simulates field conditions to assess PV module durability. Strong performance in hail testing is important for projects deployed to hail-prone regions.

Hail Stress Sequence

Hailstorms are becoming increasingly frequent and can be a severe risk to PV modules. PVEL’s HSS uses lab-manufactured hail (ice balls), the characteristics of which – size, mass, density, speed, and angle of incidence – are carefully controlled to create consistent impact energies. As a result, HSS results allow PV module buyers to easily benchmark the hail resistance of different PV module BOMs.

Why Testing Matters

Hail damage can result in major financial losses for solar assets. Several such events have been well-documented in the media.

PVEL’s testing demonstrates that the hail test required for IEC certification provides insufficient proof of hail resistance for projects in hail-prone regions.

Most hail test certifications use laboratory-created ice balls of 25 mm in diameter at 23.0 m/s velocity, which is the minimum IEC 61215 requirement. PVEL has not, thus far, observed glass breakage when conducting hail testing to IEC’s baseline certification standard.

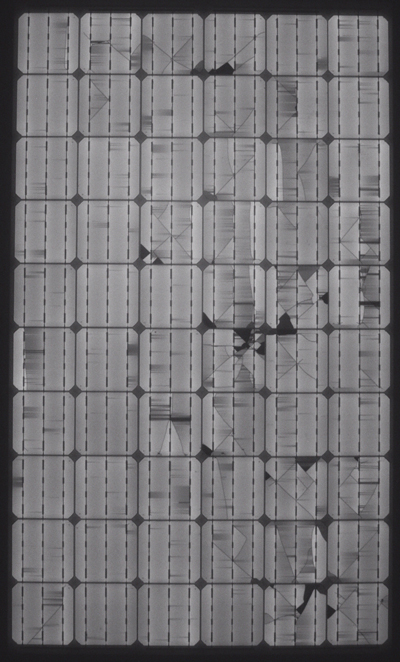

The hail-damaged modules above were deployed to an operating asset that PVEL assessed for an insurance claim. The modules passed IEC’s hail test, but they could not withstand a severe hailstorm.

”Data from insurance claims demonstrates that IEC certification does not guarantee that PV modules will survive hailstorms in the field. However, testing that evaluates PV modules on a bill of materials basis can help buyers select more durable products for deployment in hail-prone regions. We also encourage manufacturers to leverage independent testing to bring hail-optimized products to the market.

Stephen Fox, SVP of Marsh Specialty Risk Engineering & Resiliency, from a discussion at the NREL PV Reliability Workshop on property insurers’ perspectives on hail vulnerabilities of PV solar

PVEL’s hail stress sequence launched in 2021. It assesses hail-damaged modules using field data and lab simulations.

Test Procedure

The PQP hail stress sequence uses a specialized canon to fire eleven 50 mm diameter lab-manufactured hail balls at 32 m/s velocity. The hail is fired at targeted areas of the module at terminal velocity and a 0° angle, per IEC 61215.

After receiving the hail impacts, the modules are subjected to dynamic mechanical load (DML) to propagate cracks, followed by 50 thermal cycles and 10 humidity freeze cycles to simulate environmental stresses that accelerate crack-related power loss.

PVEL also offers expanded hail testing at different hail diameters and velocities for projects with varying degrees of hail risk.

Test results are designed to help:

- PV module buyers benchmark the hail resistance of different products and procure bills of materials (BOMs) that are appropriate for their projects.

- Insurers assess equipment-specific hail damage risk to inform their rates and premiums in specific project locations.

Reading HSS Test Results

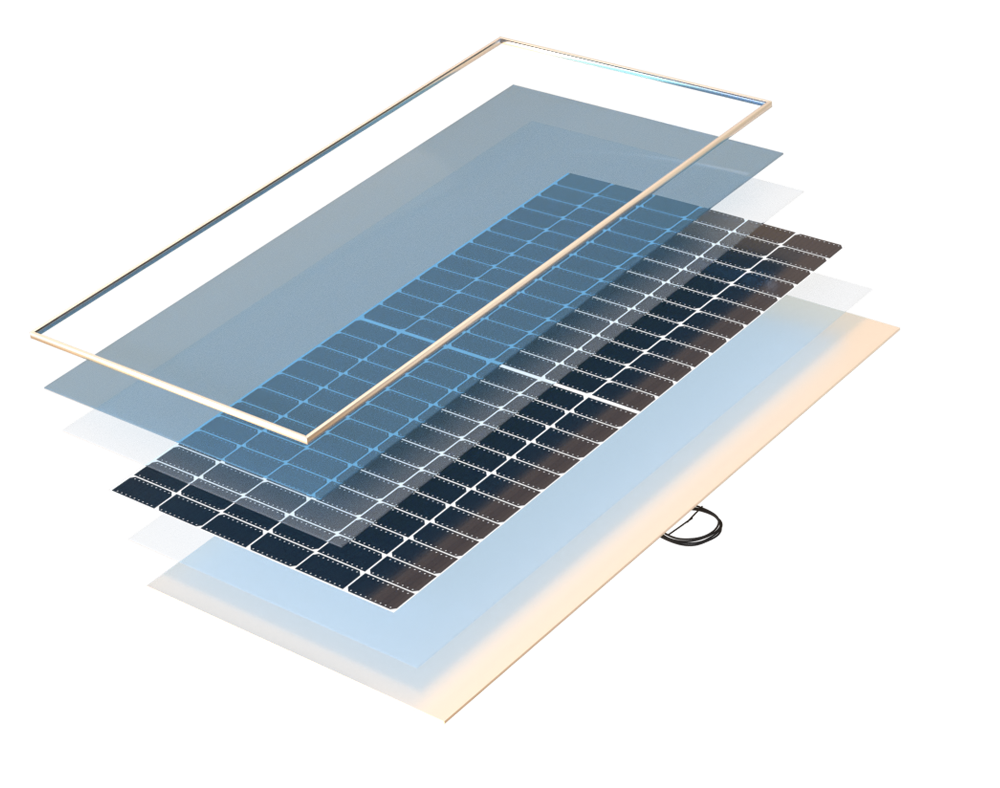

Modules that are most susceptible to hail damage may experience glass breakage during testing. Other PV modules may only suffer from cell cracks, which are visible as dark areas and broken lines in EL images and may also trigger power loss.

PVEL’s HSS test results thus far indicate that glass//glass BOMs are more resistant to cell damage from hail strikes than glass//backsheet BOMs.

In contrast, glass//backsheet designs are less likely to suffer glass breakage than glass//glass BOMs.

Glass//Glass BOM

Glass shattered with hail impacts of 50 mm at 35 m/s.

Glass//Backsheet BOM

At least 15 cells with multiple cracks after 11 hail impacts of 50 mm at 40 m/s, but the glass is intact.

Go beyond model types. Procure PV modules with top-performing bills of materials.

Join PVEL’s downstream partner network.

Sign Up